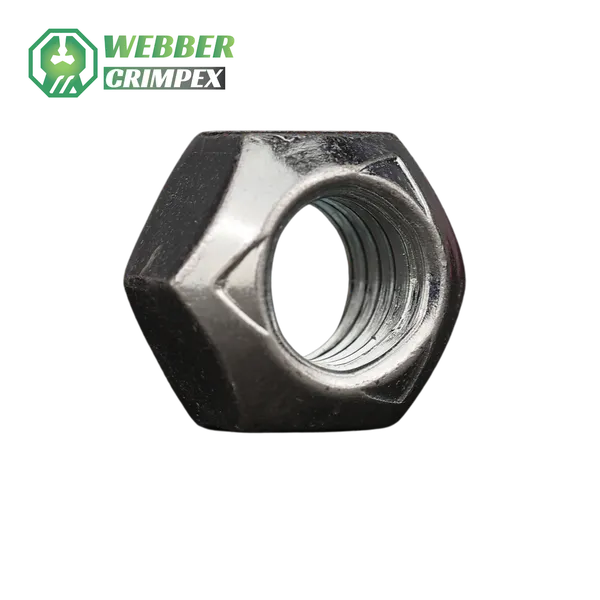

Thin / Jam Nut

Thin Nuts, also known as Jam Nuts, are low-profile hexagonal nuts used as a locking device when paired with a standard nut. Their reduced thickness makes them suitable for applications where space is limited or where an additional lock nut is required to prevent loosening under vibration.

| Parameter | Specification |

|---|---|

Product Type |

Thin Nut / Jam Nut |

Size Range |

M2 – M48 (custom sizes available) |

Material Options |

Stainless Steel, Carbon Steel, Alloy Steel, Brass |

Standards |

DIN 439, ISO 4035, BS, ASTM |

Surface Finish |

Zinc Plated, Nickel Plated, Black Oxide, Hot-dip Galvanized |

Industrial Applications

Thin / Jam Nuts are widely used in:

- Electrical panels and assemblies: Useful in compact spaces where standard nuts cannot fit.

- Automotive industry: Act as lock nuts for securing fasteners against vibration in engines and machinery.

- Construction and steel structures: Provide secondary locking in structural joints and bolted frameworks.

- Machinery and equipment: Enhance resistance against loosening in rotating or vibration-prone environments.

- Furniture and consumer products: Offer slim fastening solutions without increasing bulk.

Product Description

Thin or Jam Nuts are designed with approximately half the thickness of a standard hex nut. Their primary function is to act as a locking nut by being tightened against a standard nut to lock the pair in place. This double-nut method prevents self-loosening caused by vibration or movement. Apart from locking applications, thin nuts are also used in assembly conditions with limited space, where a full-size nut cannot be accommodated. Available in various finishes and materials, jam nuts are highly versatile for both heavy-duty and light applications.

Product specifications

- Nut Type: Low-profile hexagonal nut (half height of standard hex nut)

- Size Range: Metric M2 – M48; inch sizes available upon request

- Thread Type: ISO metric coarse/fine, UNC/UNF, BSW, BSF; custom threading on request

- Material Options: Stainless steel (A2, A4), mild steel, carbon steel, alloy steel, brass

- Surface Finish: Zinc plated, nickel plated, galvanized, black oxide, chrome plated, plain finish

- Strength Class: Available in property classes 4, 6, 8, 10; ASTM Grade A and Grade 2 available

- Tensile Strength: Up to 800–1,000 MPa depending on material and class

- Hardness: Rockwell C19–C38 for alloy steel grades

- Operating Temperature: -50°C to +400°C depending on finish and base material

- Corrosion Resistance: High when made from stainless steel or with protective coatings

- Applications: Used in lock nut combinations, limited-space installations, and vibration-prone connections

- Standards/Compliance: DIN 439, ISO 4035, BS 3692 (thin series), ASTM A563

- RoHS/REACH Compliance: Available for stainless steel and coated variants