Special Fastening

Special Fastening solutions consist of uniquely designed or engineered fasteners tailored for specific applications where standard fasteners may not provide the required performance, strength, or functionality. These fasteners often incorporate advanced locking mechanisms, specific materials, or custom geometry to meet challenging industrial needs.

| Parameter | Specification |

|---|---|

Product Type |

Special Fasteners (Locking, Structural, Customized) |

Material Options |

Stainless Steel, Alloy Steel, Carbon Steel, High-Performance Alloys |

Standard Compliance |

ISO, DIN, ASTM, ASME (varies by fastener type) |

Surface Finish |

Zinc Plated, Hot-dip Galvanized, Black Oxide, Nickel Plated, Custom Coatings |

Industrial Applications

Special Fastening solutions are widely used in:

- Aerospace and Defense: Critical for high-strength, vibration-resistant, and corrosion-proof assemblies.

- Automotive and Transportation: Ensure safety and durability under dynamic and harsh conditions.

- Construction and Infrastructure: Used in heavy-duty structural connections requiring custom design features.

- Electronics and Precision Engineering: Small, precise fastening options with locking or anti-tamper features.

- Marine and Offshore: Corrosion-resistant and high-strength fasteners for extreme environments.

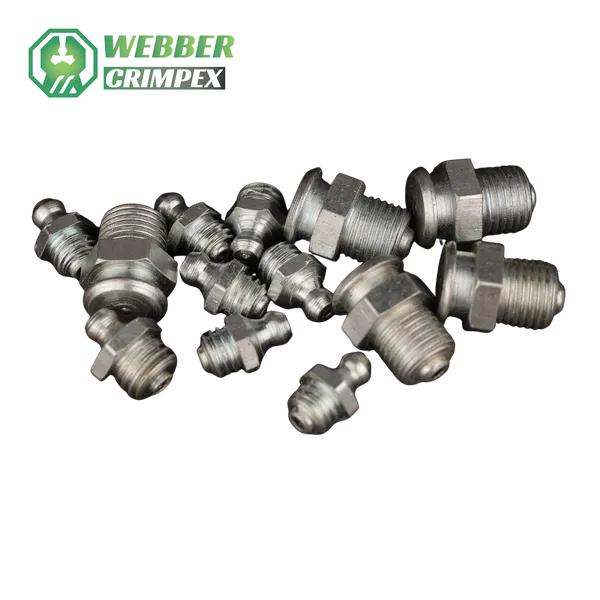

Product Description

Special Fastening includes a broad range of custom-designed or specialty fasteners such as locking bolts, security screws, structural anchors, blind rivets, threaded inserts, and precision machined fasteners. These fasteners are specially engineered to provide enhanced performance, resisting loosening from vibration, offering superior corrosion resistance, or fitting unique geometries not attainable with standard fasteners. Manufacturers of special fasteners often provide tailored solutions for specific industrial challenges, optimizing safety, efficiency, and longevity of assemblies.

Product specifications

- Types of Special Fasteners:

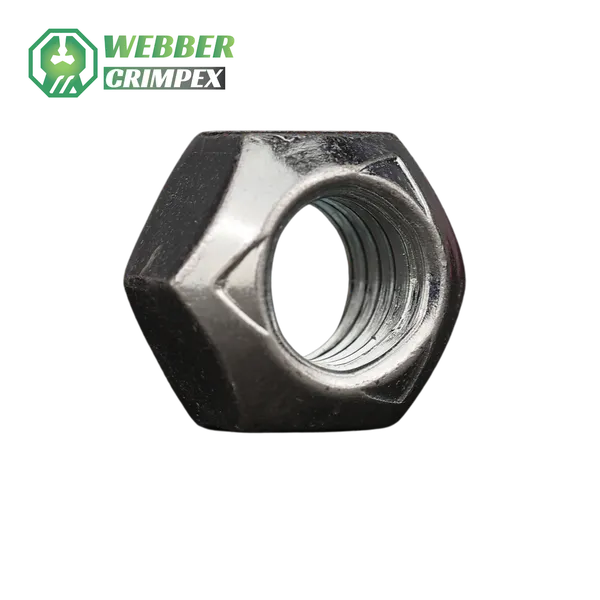

- Locking fasteners (e.g., nylon-insert lock nuts, prevailing torque nuts)

- Structural fasteners (heavy hex bolts/nuts, studs)

- Security fasteners (tamper-resistant screws, one-way bolts)

- Threaded inserts (helicoils, rivet nuts)

- Blind rivets and specialty rivets

- Custom engineered bolts and screws for specific applications

- Material Options: Various stainless steel grades, alloy steels, titanium, and corrosion-resistant coatings

- Standards/Compliance: Customized to industry requirements, including ISO, DIN, ASTM, ASME, MIL-STD

- Mechanical Properties: Vary widely based on type; typically include high tensile strength, vibration resistance, and environmental durability

- Surface Treatments: Zinc plating, galvanizing, black oxide, phosphate coating, anodizing, PTFE coating

- Applications: Industrial machinery, aerospace, automotive, marine, construction, electronics, and specialty equipment