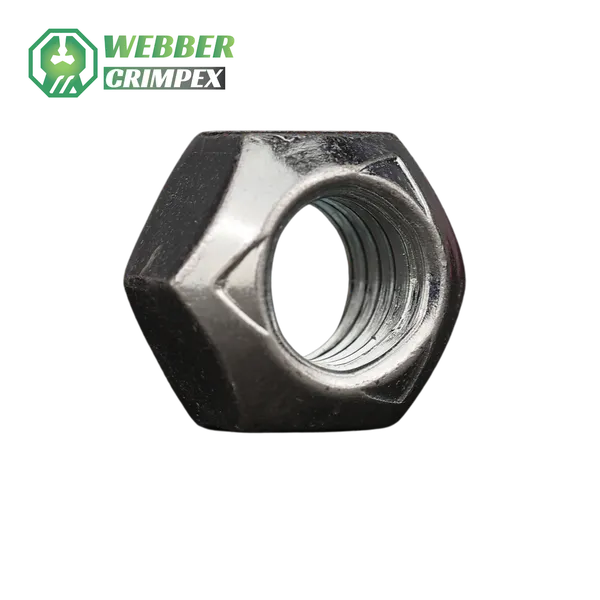

Nib Head Bolt

Nib Head Bolts are specialized fasteners featuring a low-profile head with small raised nibs underneath. These nibs bite into the surface during tightening, preventing rotation and improving grip, which eliminates the need for an additional washer in most applications.

| Parameter | Specification |

|---|---|

Product Type |

Nib Head Bolt |

Size Range |

M6 – M24 (custom sizes available) |

Material Options |

Stainless Steel, Carbon Steel, Alloy Steel |

Standards |

ISO, DIN, BS, ASTM |

Surface Finish |

inc Plated, Phosphate Coated, Black Oxide, Hot-dip Galvanized |

Industrial Applications

Nib Head Bolts are widely used in:

- Electrical panels and assemblies: Provide secure fastening with anti-rotation design for conductive areas.

- Automotive industry: Common in chassis, body assemblies, and engine components requiring vibration resistance.

- Construction and frameworks: Ensure reliable, secure fastening in steel structures, columns, and support systems.

- Railways and heavy machinery: Used in equipment exposed to constant stress and dynamic forces.

- Marine and outdoor use: Suitable with proper coatings for environments prone to corrosion.

Product Description

Nib Head Bolts are designed with a flat or slightly rounded head featuring protruding nibs beneath that grip the surface during installation. The nibs prevent the bolt from turning when torque is applied to the nut, ensuring strong fastening without slippage. They are often used in heavy-duty applications where vibration and load could otherwise loosen conventional bolts. Available in multiple grades and finishes, nib head bolts provide strength, durability, and reliable connections across a variety of industries.

Product specifications

- Head Type: Flat or slightly round head with anti-rotation nibs underneath

- Thread Type: Metric ISO coarse/fine threads; UNC/UNF on request

- Size Range: Metric M6 – M24; lengths available from 20 mm up to 200 mm (custom on request)

- Material Options: Carbon steel, alloy steel (grades 8.8, 10.9, 12.9), stainless steel (A2, A4 grades)

- Surface Finish: Zinc plating, hot-dip galvanization, phosphate coating, black oxide, plain finish

- Tensile Strength: Up to 1,200 MPa depending on grade

- Shear Strength: ~60% of tensile strength (material-dependent)

- Nib Function: Provides locking effect by biting into the material, preventing bolt spin while tightening

- Load Distribution: Low-profile head offers even clamping pressure over the surface

- Operating Temperature: -50°C to +400°C depending on base material and finish

- Corrosion Resistance: Enhanced by galvanization or stainless steel materials for outdoor and marine use

- Applications: Structural frameworks, railways, automotive chassis, heavy machinery, electrical panels

- Standards/Compliance: Manufactured to ISO, DIN, BS, ASTM standards

- RoHS/REACH Compliance: Available for specific coatings and materials