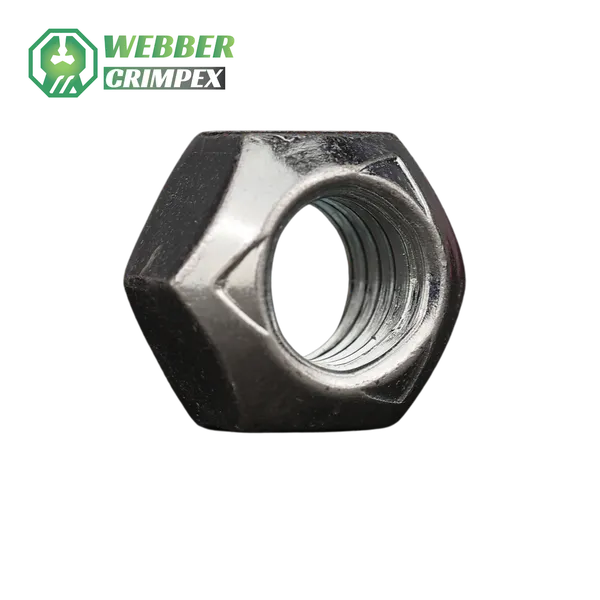

Large Hex

Large Hex Nuts are oversized hexagonal nuts designed for heavy-duty fastening applications where higher torque and load distribution are required. They provide greater surface area contact, making them suitable for structural steelwork, heavy machinery, and high-strength bolts and studs.

| Parameter | Specification |

|---|---|

Product Type |

Large Hex Nut |

Size Range |

M20 – M100 (custom sizes available) |

Material Options |

Carbon Steel, Alloy Steel, Stainless Steel |

Standards |

ASTM A563, ASTM A194, ISO, DIN, BS |

Surface Finish |

Zinc Plated, Hot-dip Galvanized, Phosphate Coated, Black Oxide |

Industrial Applications

Large Hex Nuts are widely used in:

- Electrical panels and assemblies: Provide robust fastening for heavy frameworks and enclosures.

- Automotive and heavy vehicles: Applied in trucks, trailers, and railways for secure high-load connections.

- Construction and steel structures: Commonly used with heavy hex bolts for structural joints and frameworks.

- Oil, gas, and petrochemical industries: Suitable for fastening flanges, pipelines, and high-pressure systems.

- Power plants and heavy machinery: Used in turbines, boilers, and high-tensile assemblies exposed to vibration and load.

Product Description

Large Hex Nuts are bigger in size than standard and heavy hex nuts, providing additional strength and torque-bearing capacity. Engineered for high-strength applications, they are typically used with high-tensile bolts and studs to handle structural stresses and dynamic loads. Their enlarged dimensions ensure a firm grip and improved clamping efficiency in critical assemblies. Available in a wide range of grades, coatings, and custom sizes, large hex nuts are essential in heavy-duty construction, industrial, and infrastructural projects.

Product specifications

- Nut Type: Oversized hexagonal nut with increased load-bearing surface

- Size Range: Metric M20 – M100; inch sizes also available (up to 4”)

- Thread Type: ISO metric coarse/fine, UNC/UNF; custom threading on request

- Material Options: Carbon steel, mild steel, alloy steel, stainless steel (A2/A4 grades)

- Surface Finish: Zinc plating, hot-dip galvanization, phosphate coating, black oxide, plain finish

- Strength Class: ASTM A563 Grades C, DH, ASTM A194 Grades 2H, 7, 8, 8M; Property classes 8, 10, 12

- Tensile Strength: Up to 1,200 MPa depending on grade and material

- Hardness: Typically Rockwell C22–C38 for alloy steels

- Dimensions: Larger across-flats and thickness than standard or heavy hex nuts

- Operating Temperature: -50°C to +500°C material dependent

- Corrosion Resistance: Enhanced when stainless steel or galvanized coating is applied

- Applications: Steel frameworks, pipelines, power plants, heavy construction, oil and gas industries

- Standards/Compliance: ASTM A563, ASTM A194, DIN 934 heavy series, ISO, BS standards

- RoHS/REACH Compliance: Available for stainless steel and environmentally safe coatings