Inch Thread and Metric Thread

Inch threads and metric threads are two primary standards used worldwide for fastener threading. The fundamental difference lies in the unit of measurement: inch threads measure thread pitch by threads per inch (TPI), while metric threads measure the distance between threads in millimeters (pitch).

| Parameter | Inch Thread | Metric Thread |

|---|---|---|

Measurement Unit |

Threads per inch (TPI) |

Millimeters between threads (Pitch) |

Common Standards |

Unified Thread Standard (UTS), ASME |

ISO Metric Thread System |

Thread Angle |

Typically 60° (UTS), 55° (Whitworth) |

60° |

Pitch Options |

Multiple pitches per diameter (coarse and fine) |

Coarse and fine pitch options per size |

Size Range |

Nominal diameters in inches (e.g., 1/4", 3/8") |

Nominal diameters in millimeters (e.g., M6, M10) |

Typical Applications |

Widely used in USA, Canada, UK |

Predominantly used worldwide, especially in Europe, Asia |

Tolerance System |

Fewer tolerance classes, less granular |

ISO tolerances with wide tolerance ranges |

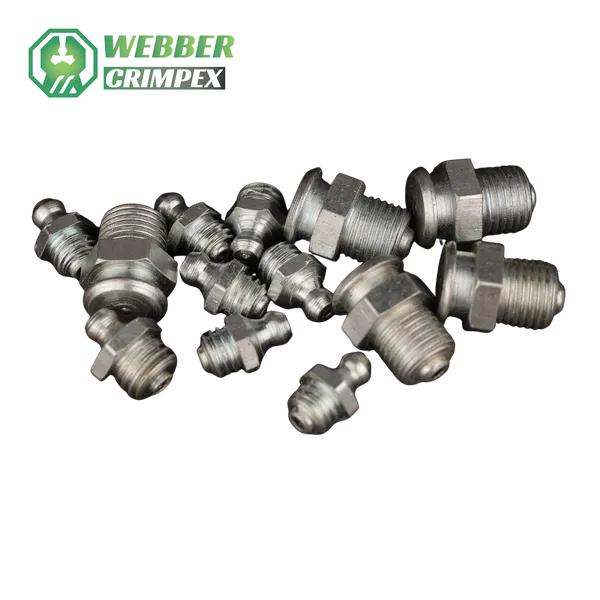

Industrial Applications

- Inch Threads: Common in North American and British industrial equipment, automotive, aerospace, and construction, especially where legacy standards apply.

- Metric Threads: Widely used internationally across aerospace, automotive, machinery, electronics, and general manufacturing due to ISO standardization and precision.

Product Description

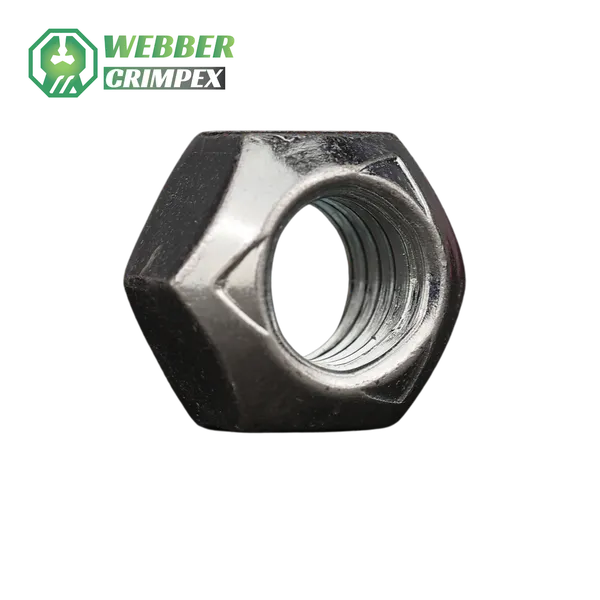

Inch threads specify the number of threads per inch (TPI), making them easier to measure in imperial units but potentially more complex to standardize internationally. Metric threads specify the pitch, or the distance between threads, giving finer control over thread engagement and strength characteristics. Metric threads simplify global manufacturing and control of tolerances with standardized pitch options and universal measurements. Both systems offer coarse and fine thread options to suit load, tension, and application requirements.

Product specifications

- Thread Angle: Both commonly use 60°, but some inch threads (Whitworth) use 55° for older standards.

- Definition: Inch = threads per inch (TPI), Metric = thread pitch in mm.

- Tolerance Classes: Metric threads provide numerous tolerance classes (e.g., 6g, 6H) for major and pitch diameters, enhancing precision. Inch thread tolerances (UNF, UNC) are less varied.

- Sizes and Fits: Inch threads sizes denoted as fractions or decimals (e.g., 1/4-20 means 1/4" diameter and 20 TPI); metric threads use M followed by diameter and pitch (e.g., M8x1.25).

- Interchangeability: Not interchangeable; correct matching fastener and nut/threaded hole is critical.

- Strength and Load: Metric threads often preferred for finer pitch offering superior tension control, but inch threads offer a broader range of pitch options per diameter.

- Common Applications: Inch threads in machinery and automotive in countries using imperial units; metric threads globally in automotive, aerospace, construction, and electronics.