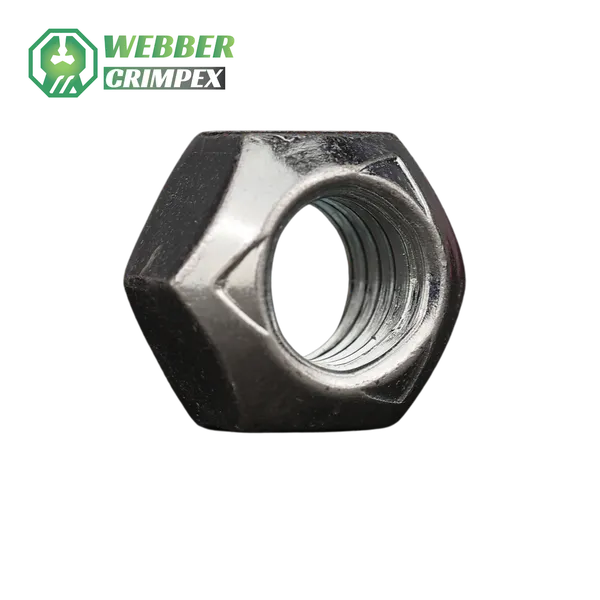

Hex Nuts

Hex Nuts are the most widely used type of nut, featuring a six-sided design that allows for efficient wrenching from multiple angles. They are paired with bolts, screws, and studs to provide secure fastening in a wide range of applications.

| Parameter | Specification |

|---|---|

Product Type |

Hex Nut |

Size Range |

M2 – M64 (custom sizes available) |

Material Options |

Stainless Steel, Carbon Steel, Mild Steel, Brass, Alloy Steel |

Standards |

DIN 934, ISO 4032, BS, ASTM |

Surface Finish |

Zinc Plated, Hot-dip Galvanized, Black Oxide, Nickel Plated |

Industrial Applications

Hex Nuts are widely used in:

- Electrical panels and assemblies: Provide reliable fastening where compact and easy-to-install nuts are required.

- Automotive industry: Used in engines, chassis, and body assemblies for vibration-resistant joints.

- Construction and structural work: Secure beams, joints, and frameworks with durable fastening.

- Machinery and equipment: Offer strong connections in rotating and static parts.

- Consumer products and furniture: Frequently used due to their versatility, availability, and ease of use.

Product Description

Hex Nuts are six-sided fasteners that mate with externally threaded bolts or screws to clamp components together. Their standard hexagonal shape makes them easy to grip with spanners or wrenches, while their compact size provides strong and reliable fastening for a variety of assemblies. Available in multiple grades, sizes, and finishes, hex nuts can be used in low-load domestic applications as well as demanding industrial environments. They are often used with washers to improve load distribution and prevent loosening under vibration.

Product specifications

- Nut Type: Six-sided (hexagonal) nut

- Size Range: Metric M2 – M64; inch sizes from #4 up to 2 1/2" also available

- Thread Type: ISO metric coarse/fine, UNC/UNF, BSW, BSF (custom threading available)

- Material Options: Stainless steel (A2, A4), mild steel, carbon steel, brass, alloy steel

- Surface Finish: Zinc plated, hot-dip galvanized, black oxide, nickel plated, chrome plated, plain finish

- Strength Class: Available in 4, 8, 10, and 12 property classes; ASTM grades also available

- Tensile Strength: Up to 1,000 MPa depending on grade and material

- Hardness: Typically Rockwell C19–C38 for alloy steel grades

- Operating Temperature: -50°C to +400°C (varies by base metal and coating)

- Corrosion Resistance: Enhanced in stainless steel and plated finishes; ideal for outdoor and marine applications

- Applications: Found in construction, automotive, mechanical, electrical, and household uses

- Standards/Compliance: DIN 934, ISO 4032, ISO 4033, BS 1768, ASTM A563

- RoHS/REACH Compliance: Available in specific coatings and stainless steel options