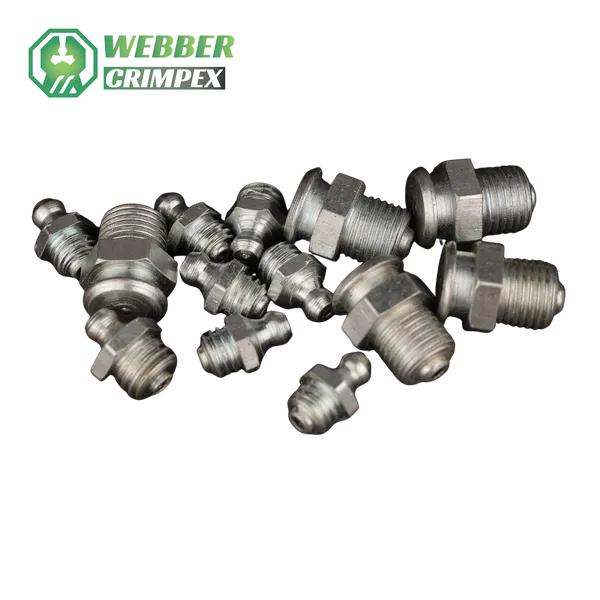

Grub Screws

Grub Screws, also known as set screws, are headless fasteners generally used to secure an object within or against another object, preventing relative motion. They are tightened using an internal hex (Allen) or slotted drive, ideal for applications in confined spaces.

| Parameter | Specification |

|---|---|

Product Type |

Grub Screw / Set Screw |

Size Range |

M1.6 – M20 (commonly available sizes) |

Material Options |

Stainless Steel, Alloy Steel, Carbon Steel |

Standards |

ISO 4026 (DIN 913), ISO 4027, DIN 914, ASTM |

Surface Finish |

Plain, Zinc Plated, Black Oxide, Nickel Plated |

Industrial Applications

Grub Screws are widely used in:

- Electrical panels and assemblies: Secure shafts, collars, and couplings to prevent slippage.

- Automotive industry: Lock gears, pulleys, and collars on shafts.

- Machinery and equipment: Provide secure locking in rotary components and assemblies.

- Precision instruments: Offer compact fastening where headless screws are preferred.

- Appliances and consumer products: Used in areas requiring low-profile or hidden fastening.

Product Description

Grub Screws are threaded fasteners without an external head, designed to be driven by wrenching an internal socket or slot. They are commonly used to lock parts like collars or gears on shafts, using different point types (flat, cone, cup, dog, or knurled) to suit the holding force and surface protection required. Available in various materials and finishes to provide corrosion resistance and strength, grub screws are an essential component in mechanical assemblies needing secure, low-profile fastening solutions.

Product specifications

- Screw Type: Headless, socket or slotted drive

- Size Range: Metric M1.6 to M20; lengths vary by diameter

- Thread Types: ISO metric coarse threads predominantly; UNC/UNF on request

- Material Options: Stainless steel (A2, A4), alloy steel (grade 12.9 typical), carbon steel

- Point Types: Flat, cone, cup, dog, knurled cup, oval, and others depending on application

- Surface Finish: Plain, zinc plated, black oxide, nickel plated, phosphate coated

- Mechanical Strength: Alloy steel versions up to property class 12.9; stainless versions up to A4-80

- Drive Types: Hex socket (Allen), slotted available for small sizes

- Operating Temperature: -50°C to +400°C depending on material and finish

- Corrosion Resistance: Enhanced in stainless steel and coated variants for outdoor/industrial use

- Applications: Locking, securing, anti-rotation, resistance to vibration or movement in assemblies

- Standards/Compliance: ISO 4026, DIN 913, ISO 4027, DIN 914, ASTM