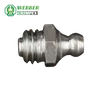

Grease Nipple

Grease Nipples are lubrication fittings designed to allow controlled application of grease into mechanical assemblies. They provide a secure connection for grease guns and ensure smooth operation and extended service life of moving parts by minimizing friction and wear.

| Parameter | Specification |

|---|---|

Product Type |

Grease Nipple |

Size Range |

M6 – M12 (custom BSP / NPT threads available) |

Material Options |

Carbon Steel, Stainless Steel, Brass |

Standards |

ISO, DIN, BS, SAE, IS |

Surface Finish |

Zinc Plated, Nickel Plated, Black Oxide, Brass Finish, Plain |

Industrial Applications

Grease Nipples are widely used in:

- Automotive industry: Lubrication points in suspensions, steering systems, universal joints, and bearings.

- Heavy machinery and construction equipment: In excavators, loaders, cranes, and tractors to ensure reliable lubrication without disassembly.

- Industrial machinery: Applied in gearboxes, pumps, motors, and conveyors for continuous maintenance.

- Railways and aerospace: Provide secure and consistent lubrication in critical assemblies where reliability is vital.

- Agricultural equipment: Used in ploughs, harvesters, and tractors for prolonged performance under heavy loads and dusty conditions.

Product Description

Grease Nipples, also known as Zerk fittings or grease fittings, are precision-engineered lubrication components that allow clean, controlled injection of grease into bearings and moving assemblies. By serving as a one-way valve, they prevent dirt, moisture, and contaminants from entering the lubrication point while enabling easy maintenance using grease guns. Available in different angles and thread sizes, they enhance machinery life and reduce downtime by ensuring consistent lubrication even in harsh environments.

Product specifications

- Product Design: Available in straight, 45°, and 90° angled designs with ball check valve for grease control

- Installation Method: Screw-in type fitting compatible with metric, BSP, and NPT threads

- Size Range: Metric threads M4–M20; inch/BSP/NPT sizes on request

- Material Options: Carbon steel, stainless steel (AISI 303/304/316), brass

- Thread Type: ISO metric, BSP, BSPT, NPT, SAE threads available

- Operating Pressure: Suitable for high-pressure grease injection up to 10,000 psi (depending on design and material)

- Anti-Leak Design: Ball check valve prevents grease backflow and contaminant ingress

- Surface Finish: Zinc plated, nickel plated, black oxide, brass finish, or plain

- Corrosion Resistance: Enhanced with stainless steel or protective coatings for outdoor and harsh conditions

- Temperature Range: -30°C to +200°C depending on grease and material compatibility

- Compliance Standards: DIN 71412, ISO, SAE standards

- RoHS/REACH Compliance: Environmentally safe options available