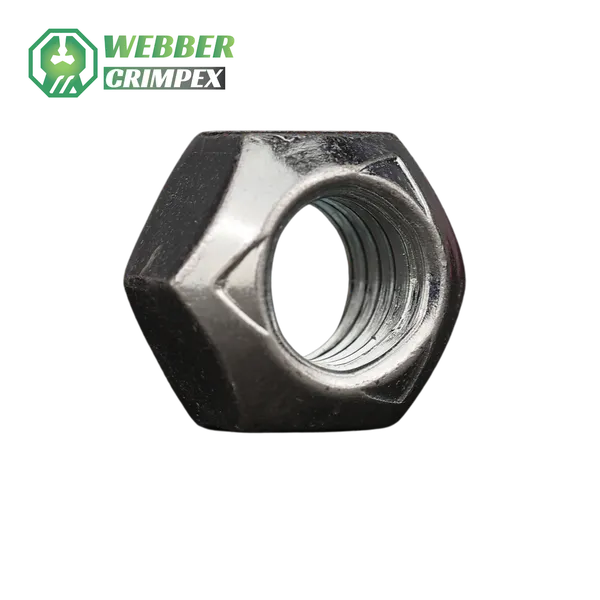

Flange Bolts

Flange Bolts are high-strength fasteners with a built-in washer-like flange beneath the hexagonal head. The flange distributes the clamping load, reducing the risk of damage to the material and eliminating the need for a separate washer in many applications.

| Parameter | Specification |

|---|---|

Product Type |

Flange Bolt |

Head Type |

Hex Head with Integrated Flange |

Size Range |

M6 – M24 (custom sizes available) |

Material Options |

Stainless Steel, Carbon Steel, Alloy Steel, Mild Steel |

Standards |

DIN 6921, ISO, BS, ASTM |

Surface Finish |

Zinc Plated, Hot-dip Galvanized, Phosphate Coated, Black Oxide |

Industrial Applications

Flange Bolts are widely used in:

- Electrical panels and assemblies: Provide firm fastening with fewer components by eliminating extra washers.

- Automotive industry: Commonly used in engines, transmissions, and chassis assemblies for vibration-resistant fastening.

- Construction and heavy machinery: Secure structural and mechanical components in demanding applications.

- Agricultural equipment: Offer high clamping strength for machinery exposed to outdoor conditions.

- Oil, gas, and power sectors: Used in high-pressure and vibration-prone environments for stable connections.

Product Description

Flange Bolts are designed with a hexagonal head and a circular flange beneath, which distributes the fastening pressure over a larger surface. This design improves load distribution, prevents loosening under vibration, and reduces assembly time by eliminating separate washers. Flange bolts are available with serrated or non-serrated flanges, serrated types provide additional locking power, while non-serrated offer smooth load distribution. Due to their strength and reliability, flange bolts are widely used in automotive, construction, and heavy equipment industries.

Product specifications

- Head Design: Hex head with integrated flange

- Types: Serrated flange bolts (anti-loosening) and non-serrated flange bolts (smooth load distribution)

- Thread Type: Metric ISO coarse/fine; UNC/UNF available on request

- Size Range: M6 – M24; lengths from 15 mm up to 200 mm (custom available)

- Material Options: Stainless steel (304/316), carbon steel, mild steel, alloy steel (grade 8.8, 10.9, 12.9)

- Surface Finish: Zinc plating, hot-dip galvanization, phosphate coating, black oxide, plain finish

- Flange Diameter: Proportional to bolt size; typically 1.5–2 times nominal diameter

- Tensile Strength: Up to 1,200 MPa depending on grade

- Shear Strength: ~60% of tensile rating (material dependent)

- Locking Mechanism: Serrated flange bites into material to prevent loosening under vibration

- Operating Temperature: -50°C to +400°C depending on base material and finish

- Corrosion Resistance: Excellent with stainless steel and galvanization for outdoor/harsh environments

- Applications: Automotive fasteners, heavy machinery, construction frameworks, engines, and industrial assemblies

- Standards/Compliance: DIN 6921, ISO 4162, BS, ASTM specifications

- RoHS/REACH Compliance: Available for coatings and stainless variants