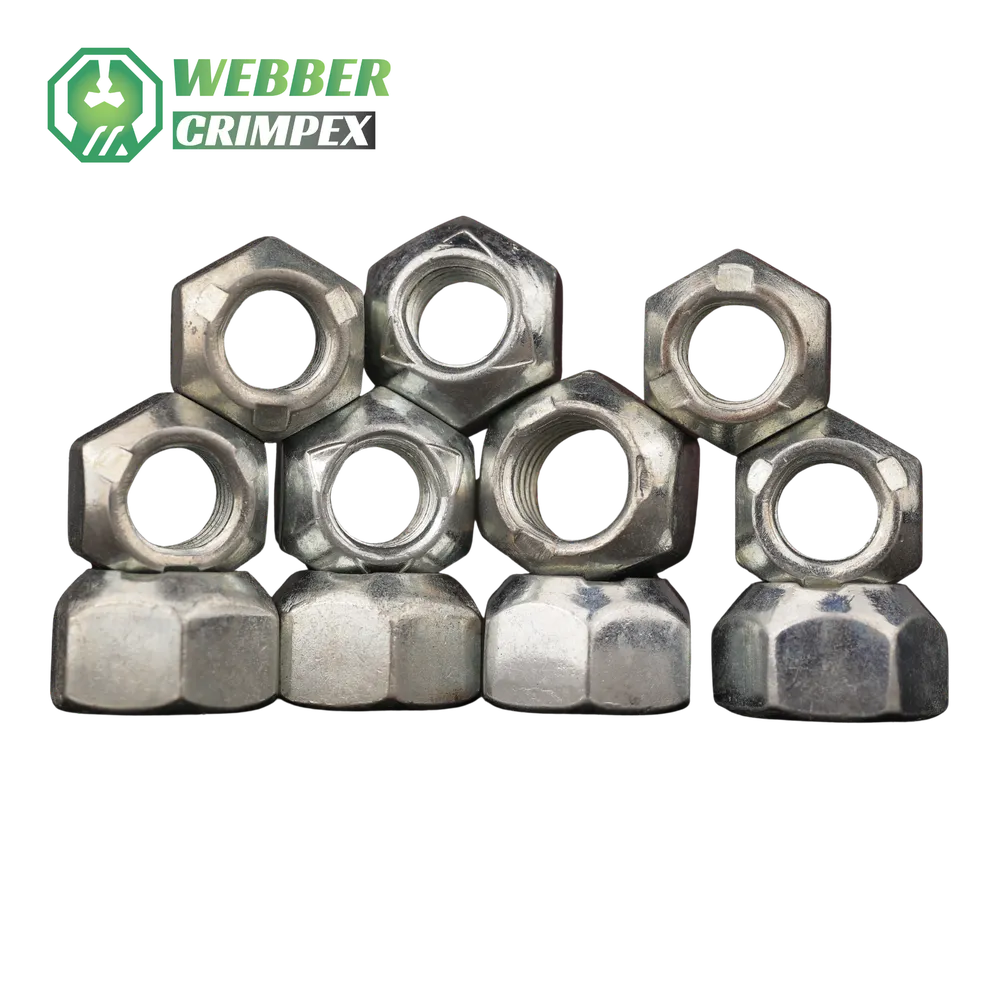

Crimping Nut

Crimping Nuts are specialized fasteners designed to provide a secure threaded connection in thin sheet materials where traditional tapping methods are not possible. These nuts are mechanically crimped into the material, offering strong load-bearing threads while preventing rotation and pull-out.

| Parameter | Specification |

|---|---|

Product Type |

Crimping Nut |

Size Range |

M2 – M30 (custom options available) |

Material Options |

Stainless Steel, Carbon Steel, Brass, Aluminum |

Standards |

ISO, DIN, BS |

Surface Finish |

Zinc Plated, Nickel Plated, Black Oxide, Plain |

Industrial Applications

Crimping Nuts are widely used in:

- Electrical panels and assemblies: Provide firm threaded connections in thin sheets where conventional nuts can’t be used.

- Automotive components: Ensure durable fastening in lightweight assemblies such as dashboards, trims, and panels.

- Aerospace structures: Offer vibration resistance and secure threads in lightweight alloys.

- Consumer electronics: Used in casings, enclosures, and devices requiring compact fastening without welding.

- Construction hardware: Applied in sheet metal and framework connections where reliability is critical.

Product Description

Crimping Nuts are permanent installation fasteners that create a robust threaded insert in soft or thin sheet materials. They are installed by applying crimping pressure that locks the nut firmly into position, resisting both torque and pull-out. This makes them an ideal solution in designs that require reliable threads in lightweight materials without compromising strength. Available in metric and inch sizes, they come in various materials and surface coatings to match both functional and environmental requirements.

Product specifications

- Product Design: Cylindrical or hexagonal body with knurled or grooved outer surface for anti-rotation

- Installation Method: Press-fit and crimped into thin sheets using hand tools or hydraulic presses

- Size Range: Metric sizes M2 to M12; inch sizes available on request

- Material Options: Stainless steel (AISI 304/316), carbon steel, brass, and aluminum

- Thread Type: Standard ISO metric coarse/fine thread; UNC/UNF available on request

- Panel Thickness Compatibility: Suitable for sheets from 0.5 mm to 3.0 mm

- Pull-Out Strength: High retention force depending on material and panel thickness

- Anti-Rotation Feature: Knurled/grooved outer profile prevents spinning in the sheet

- Surface Finish: Zinc plated, nickel plated, black oxide, anodized (for aluminum), or plain finish

- Corrosion Resistance: Enhanced with stainless steel or protective coatings

- Applications in Vibration Zones: Maintains secure fastening even under vibrations and stress

- Operating Temperature: -50°C to +300°C depending on material choice

- Compliance Standards: DIN, ISO, and BS specifications

- RoHS/REACH Compliance: Available for environmentally safe applications