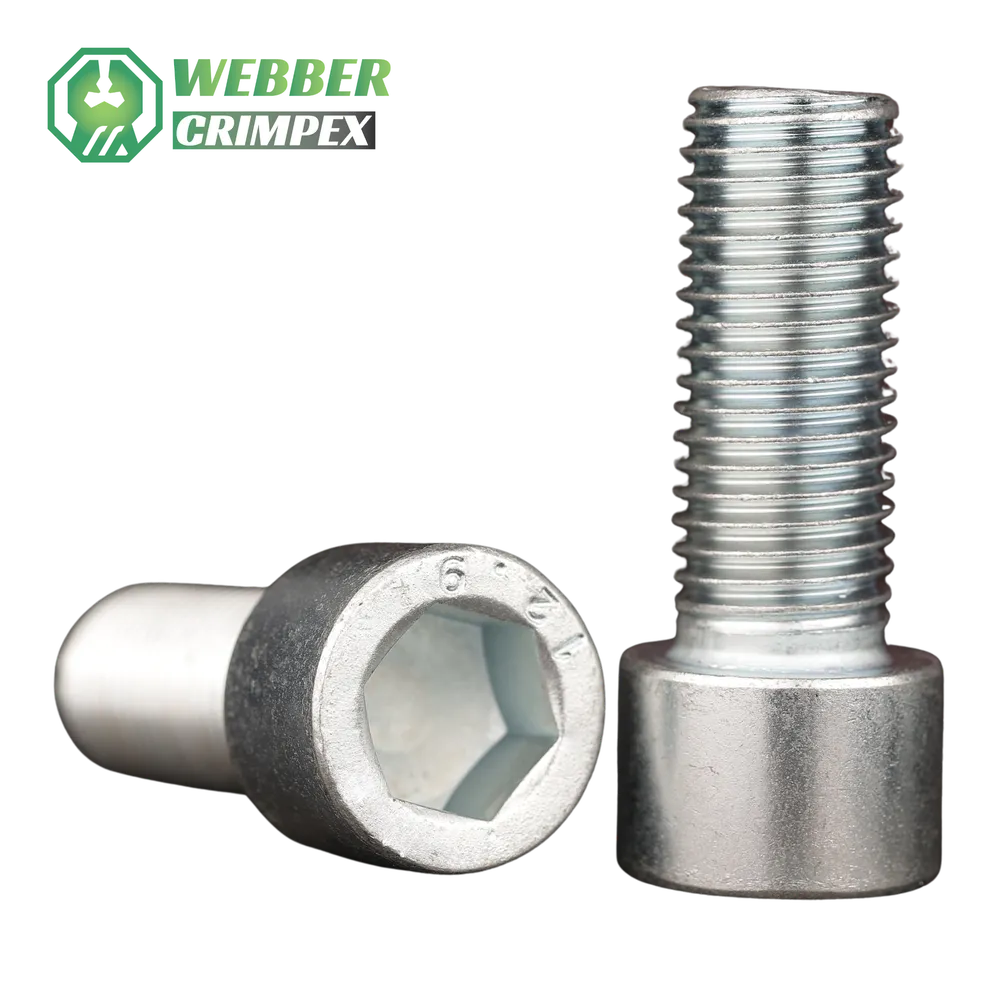

Allen Bolts

Allen Bolts, also known as Socket Head Cap Screws, are precision fasteners with a cylindrical head and internal hex drive (Allen key drive). They allow high torque application with minimal risk of slippage and are ideal for applications where limited space requires flush or recessed fastening.

| Parameter | Specification |

|---|---|

Product Type |

Allen Bolt / Socket Head Cap Screw |

Drive Type |

Internal Hex (Allen Key) |

Size Range |

M3 – M36 (custom sizes available) |

Material Options |

Alloy Steel, Stainless Steel, Carbon Steel |

Standards |

DIN 912, ISO 4762, BS, ASTM |

Surface Finish |

Zinc Plated, Black Oxide, Hot-dip Galvanized, Nickel Plated |

Industrial Applications

Allen Bolts are widely used in:

- Electrical panels and assemblies: Provide secure fastening in tight spaces with flush finish.

- Automotive industry: Common in engines, suspensions, and high-stress joints requiring precision fastening.

- Aerospace and defense: Used in critical assemblies demanding high strength-to-weight ratio.

- Machinery and equipment: Ideal for precision components requiring reliable, vibration-resistant joints.

- Furniture and consumer goods: Provide neat aesthetics with concealed fastening.

Product Description

Allen Bolts are designed with a smooth cylindrical head and an internal hex socket for Allen key tightening. This design allows greater torque transfer without damaging the tool or the fastener. Allen bolts are suitable for applications with limited clearance, enabling recessed or countersunk installation while maintaining strong clamping force. Available in high-tensile alloy steel for heavy-duty use, as well as stainless steel for corrosion-resistant applications, these fasteners are widely appreciated for their combination of strength, precision, and clean appearance.

Product specifications

- Head Type: Cylindrical (socket head cap screw design)

- Drive Type: Internal hex socket (Allen key)

- Size Range: Metric M3 – M36; lengths from 10 mm up to 300 mm (custom available)

- Thread Type: ISO metric coarse/fine, UNC/UNF, other standards on request

- Material Options: High-tensile alloy steel (grades 8.8, 10.9, 12.9), stainless steel (A2, A4), carbon steel

- Surface Finish: Black oxide, zinc plating, hot-dip galvanization, nickel plating, chrome plating

- Tensile Strength: Up to 1,220 MPa depending on grade and material

- Shear Strength: ~60% of tensile rating (varies with material class)

- Head Dimensions: Compact cylindrical design allows use in countersunk or flush assemblies

- Torque Capacity: Higher torque application with Allen key reduces risk of cam-out compared to slotted drives

- Operating Temperature: -50°C to +400°C (material dependent)

- Corrosion Resistance: Excellent in stainless steel and plated versions, ideal for outdoor and marine use

- Applications: Automotive, aerospace, machinery, construction, furniture, consumer products

- Standards/Compliance: DIN 912, ISO 4762, BS 4168, ASTM A574

- RoHS/REACH Compliance: Available for stainless and coated options