Understanding Crimped Nuts and Standard Nuts: What Sets Them Apart?

Fasteners are essential components in mechanical assemblies, providing the critical function of holding parts together. Among the various types of nuts available, crimped nuts and standard nuts are commonly used for different applications depending on the environment and performance requirements. Understanding their unique characteristics and differences can help you make the right choice for your projects.

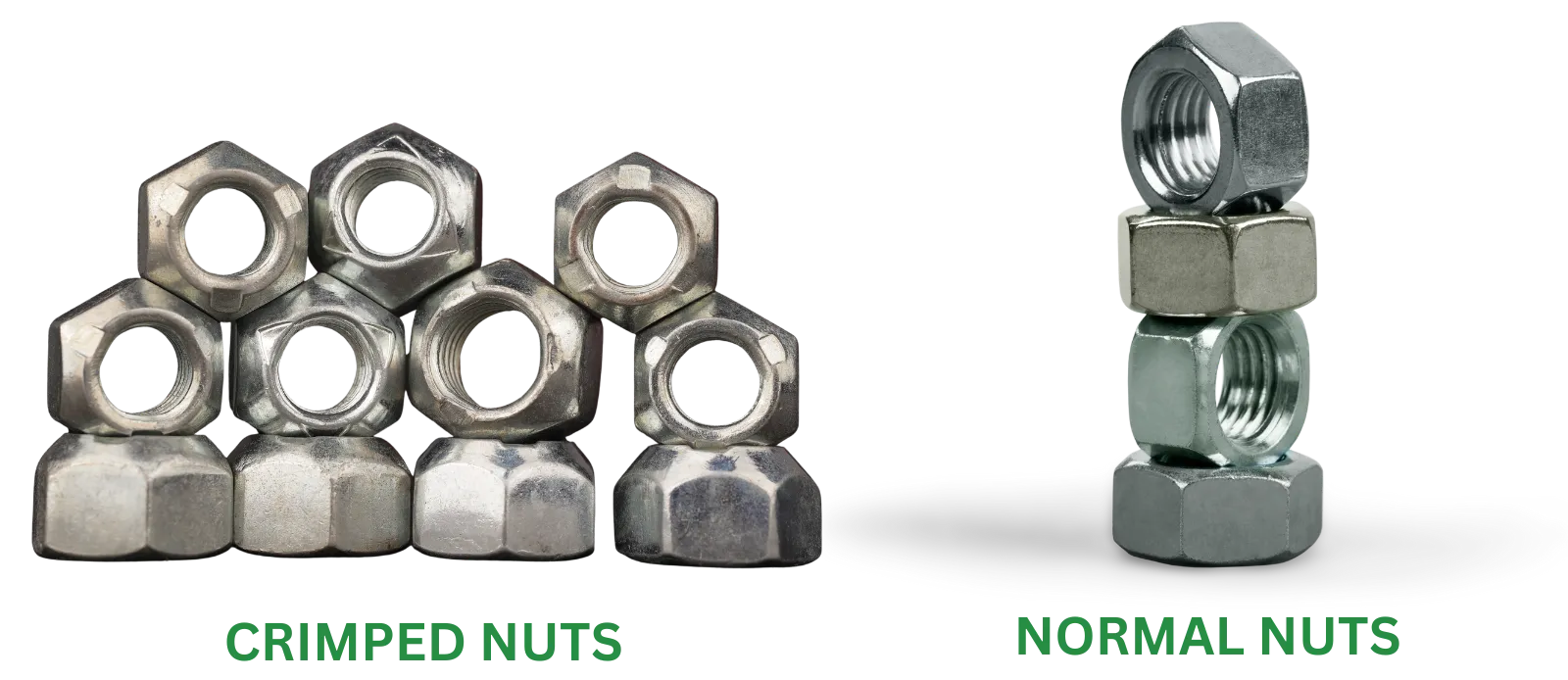

What Are Crimped Nuts?

Crimped nuts, sometimes called lock nuts, are designed to resist loosening caused by vibration or mechanical stress. These nuts have a specially shaped or compressed top section that slightly deforms the threads inside, creating extra friction when fastened onto a bolt. This deformation acts as a locking feature, preventing the nut from backing off unintentionally. Crimped nuts are often employed in environments where safety, reliability, and heavy vibration are paramount and unavoidable, such as automotive manufacturing, heavy machinery, and aerospace components. The installation may require specific tools that press or crimp the nut into place, ensuring a secure and vibration-resistant fastening.

Understanding Standard Nuts

Standard nuts, also known as regular or hex nuts, are the most basic type of nut with uniform threading. They fasten components together by threading onto bolts or screws, relying primarily on the thread engagement and friction alone. While they are easy to use, standard nuts do not have any inherent locking features, making them less suitable for use in situations where vibrations or dynamic loads might cause them to loosen. Generally, they are perfect for everyday fastening tasks where the load is static or mild, such as structural assembly, furniture, and general machinery.

| Feature | Crimped Nuts | Standard Nuts |

|---|---|---|

Locking Capability |

Locking via thread deformation |

No inherent locking feature |

Vibration Resistance |

High resistance to loosening |

Low; may loosen under vibration |

Typical Use Cases |

High-stress or vibration-prone areas |

General fastening applications |

Installation Method |

Requires crimping or pressing tools |

Simple manual tightening |

Reusability |

Limited due to deformation |

High; can be reused often |

Choosing the Right Nut for Your Application

Selecting between crimped and standard nuts depends on the operational environment of your project. If your application faces vibrations, movement, or fluctuating loads, crimped nuts provide that extra security to keep fasteners tight. For most routine fastening needs where loads are stable and vibrations minimal, standard nuts are an effective, economical choice.

This overview should help clarify the distinctions between crimped and standard nuts, enabling better decisions for durable and safe assembly design.

If more detailed technical specifications or installation guidance is needed, contact us.