Complete Guide to Fasteners: Types, Materials, and Applications

Fasteners are the unnoticed framework of our constructed environment, as is clear when you walk into any hardware shop. Fasteners silently keep modern life together, from the small smartphone screw to the huge bolts holding structure supports. But even with their widespread use, picking the correct fastener is never easy.

Making sensible decisions about type, material, and installation are important to the efficiency, duration, and safety of any project.

This guide gathers industry knowledge, latest technologies, and useful suggestions into a single resource. Consumers will be prepared to choose the appropriate fastener for any situation at the end, even if whether they are engineers, do-it-yourselfers, or purchasing experts.

What is a fastener?

Hardware tools called fasteners are made to mechanically attach or connect two or more things. On the surface, their work appears straightforward, but behind it is a world of material science and engineering precision. In addition, every option from rivet to bolt, titanium to steel has an impact on both cost and performance.

Consider an automobile, for example: thousands of fasteners maintain the engine, body panels, and safety elements in place. Structural fasteners used in construction must withstand years of strain, weather, and earthquakes. To prevent damage to circuits and housings, electronics require small fasteners with extremely precise torque control.

Types of Fasteners

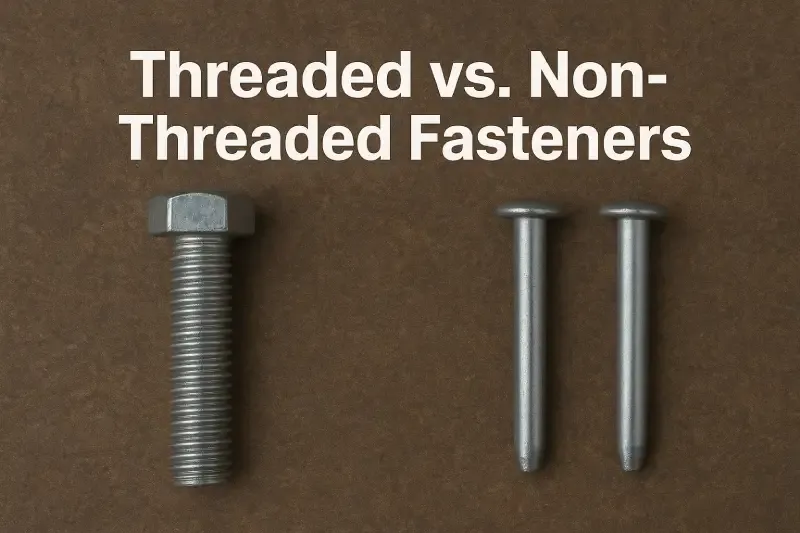

Threaded Fasteners: Strong and Adaptable

Threaded fasteners are necessary to most projects. Spiral grooves are used in these solutions to efficiently grab materials.

Bolts are perfect for situations requiring strength and ease of disassembly because they require nuts for assembly. They are frequently used in structural and mechanical applications.

In fact, hex bolts are present in the majority of steel frameworks, whereas anchor bolts stabilize the foundations of heavy machinery.

As a result, screws make their own threads in the material they are fastened to. They can do anything from electronics to woodworking. Because they offer accurate and dependable attachments, machine screws are particularly helpful in electronics.

Bolt assemblies are supported by nuts and washers. Popular lock nuts and hex nuts are resistant to loosening and vibration. Washers, which are usually ignored, spread out loads over a greater surface area.

Non-Threaded Fasteners:

Alternatives to Long-Term and Accurate Needs

Non-threaded fasteners are frequently used by engineers when they require durable bonding.

In shipbuilding and aviation rivets are required. Once set a rivet is hard to remove. When only one side of the joint is accessible blind rivets give flexibility and allow installation.

The key to pins like dowel pins is accuracy. They ensure gears, fixtures and jigs stay fixed in place while in use by aligning connecting components. Holding clips give fast assembly and disassembly and increase production line efficiency.

Choosing the Right Material: The Facts of Fastener Performance

Steel: The Industry Standard

Do you need strength at the right price? Carbon steel fasteners are cheap and widely available. But zinc coating or galvanization is often used since plain steel is prone to corrosion.

But stainless steel is rust proof. In food processing, chemical and shipping industries it’s more expensive but worth it. Even in harsh conditions grades like 304 and 316 will give long life.

Specialty Materials: To Fulfill Even More Demanding Requirements

For lightweight components where weight matters as much as anything else in the airplane business aluminum fasteners are excellent. To avoid galvanic corrosion with other metals they should be used with some care.

Titanium is prized for its high strength-to-weight advantage and long-lasting quality. Though costly it's frequently worth the price for high-stress applications of advanced engineering, space and medical use.

Brass and bronze are excellent materials used for electrical systems due to their conductive and corrosion-resistant capabilities.

Nylon and other polymers are used for special applications where electrical insulation is needed or parts should be lightweight and non-magnetic.

Advanced Fastener Coatings and Surface Treatments

Surface technology developments allow fasteners to perform under severe conditions.

Hot-dip galvanizing and zinc plating are economical anti-corrosion coatings. For improved further results, you could use ceramic or nano-coatings with excellent resistance from chemicals and wear.

Passivation and anodizing are particularly worthwhile with stainless steel and with aluminum, offering complementary chemical-resistant coatings while adding looks.

Choice of Fasteners: A Practical Handbook

The process of selecting isn't a process of guessing. Try this tested method:

Analyze Loads:

Consider the final ultimate tensile and shearing loads a fastener will encounter. Structural steel may call for high-tension bolts; electrical equipment may require precision more than brute power.

Assess Environment:

Will the fastener encounter moisture, heat, chemicals, or exposure from the elements? Select corrosion-resistant coatings and materials as such.

Plan for Installation:

Access may be restricted and a blind rivet may thus suffice. For designs with high maintenance intensity, make use of parts with straightforward inspectability or removability.

Verify Industry Standards. Depend on international standards like ASTM, ISO, and SAE for grades of fasteners with a view of compatibility and safety.

Uses: Fasteners For Industries

Construction: Building Across Decades

In the construction business, you can't go too far without fasteners. Structural bolts, anchor rods, and other concrete anchors are utilized to build skyscrapers, bridges, and high-rises that last generations. Here reliability becomes a requirement.

Automotive: Built to Perform

Cars depend upon a sophisticated tapestry of fasteners. Contemporary cars are required to be both lightweight and durable, and therefore high-tensile vibration-resistant bolts are used in tandem with specialty composite or stainless-steel fasteners. Lock nuts, as an example, avert catastrophe when cars encounter vibration and shock during travel.

Aerospace: Frontiers of Human

When used in aerospace production, every gram matters. Aircraft parts are fastened with titanium, first-class alloys, and permanent rivets. Withstanding severe vibration and stress once airborne, the fasteners face the industry's toughest tests and standards.

Electronics: Miniaturization and Precision

Tiny fasteners, at times as narrow as a strand of hair, are utilized in laptops, telephones, and circuit boards. Here accuracy, insulation, and prevention of damage are the priority.

Energy and Heavy Industry

The environments range from wind turbines to oilrigs and all of which require high level corrosion resistance, mechanical reliability, as well as code compliance. Smart fasteners that have their own condition monitoring are just starting to be used here.

Emerging Tech: AI, IoT and More

The fastener world is changing faster than anyone can remember, not just because of demand from customers and regulations, but also because of the all-presence of smart technology.

AI-Powered Fastener Selection

AI models, which have been trained on failure data and load simulations, are helping engineers to specify the best fasteners for complex projects. This approach minimizes risk and saves design time.

IoT and Smart Fasteners

The latest “smart” fasteners have embedded sensors that are able to communicate real-time data on tension, vibration and temperature. Such cuts on bridges or towers send out alerts far in advance of a visible failure, allowing for predictive maintenance and preventing disasters.

Construction and aviation industries are among a growing number of early adopters, while demand is also increasing in heavy equipment and transportation.

Current trends in sustainability

New regulations and the need for businesses to be more sustainable are driving the development of eco-friendly fasteners, such as recyclable metals and biodegradable plastic fasteners. In an effort to cut waste and carbon emissions, businesses are altering their supply chains.

3D Printing and Customization

Additive manufacturing (3D printing) provides for building small quantities of custom fasteners for prototypes and high-performance uses. That makes it possible to accelerate development along with close customer interaction.

Best Practices: Installation, Quality, and Maintenance

Correct torque and tight

Improperly torqued fasteners break or come loose. Regardless, always use the manufacturer's torque spec and calibrated wrenches. Especially with multi-bolt joints, alternate tightening pattern ("star pattern") loads stress correctly.

Checking and Testing Loads

Visually check all fasteners for damage or improper assembly. Large projects usually put assemblies through test loads, checking they meet or exceed specification.

Planned Maintenance

Critical infrastructure needs regular fastener checks for corrosion, loosening, or fatigue. Smart fasteners do one better by automating it through real-time diagnosis.

Replacement Planning

Don't wait until it's going to break. Good maintenance programs use history (sometimes filtered through artificial-intelligence platforms) to forecast replacement needs and avoid costly reactive repair and needless downtime.

Conclusion

Fasteners are more than simple connectors. They make all the difference between how strong, how safe, and how long-lived every piece of building, every device, every vehicle will be.

With industries incorporating wiser, cleaner, and fresher technology, it will make all the difference in the world to make smart choices about fasteners. With frequent updates on information and judicious choices, workers today will help construct tomorrow one connection at a time.

Frequently Asked Questions (FAQ):

Think of bolts as team players, they always need a nut to hold things together, while screws are more independent and twist straight into the material on their own.

If you want to avoid rust, choose stainless steel or properly coated fasteners, which can withstand moisture like champions.

Use a rivet for permanent bonds, but choose bolts if you may need to disassemble later.

Smart fasteners have built-in sensors that monitor tension and vibration, giving you an early warning before anything fails.

Consider the materials you are joining; thicker and denser materials require larger, stronger fasteners. Most brands provide sizing charts to help you choose.

Yes, fasteners are increasingly made with recycled or biodegradable materials, making sustainable choices easier.

Washers are like insurance; they distribute force, preventing surface damage during tightening.

Modern fasteners use ceramic or zinc-nickel coatings to prevent rust and ensure sustained performance.

Workers who use high-tensile fasteners are essential for heavy machinery and areas where objects move, vibrate, or are subjected to difficult conditions.

Smart fasteners, eco materials, and AI-powered part selection are currently trending.