Our Valued Clients

Trusted by businesses across industries, delivering exceptional results and building lasting partnerships.

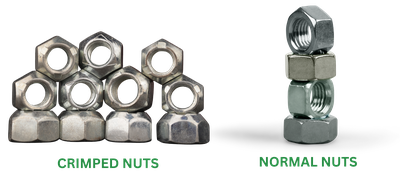

We are proud to serve a diverse range of industries with high-quality crimped nuts and bolts, trusted for their precision, durability, and performance. Our clients include leading manufacturers, engineering firms, and construction companies who rely on us for dependable fastening solutions.